A message from oli.

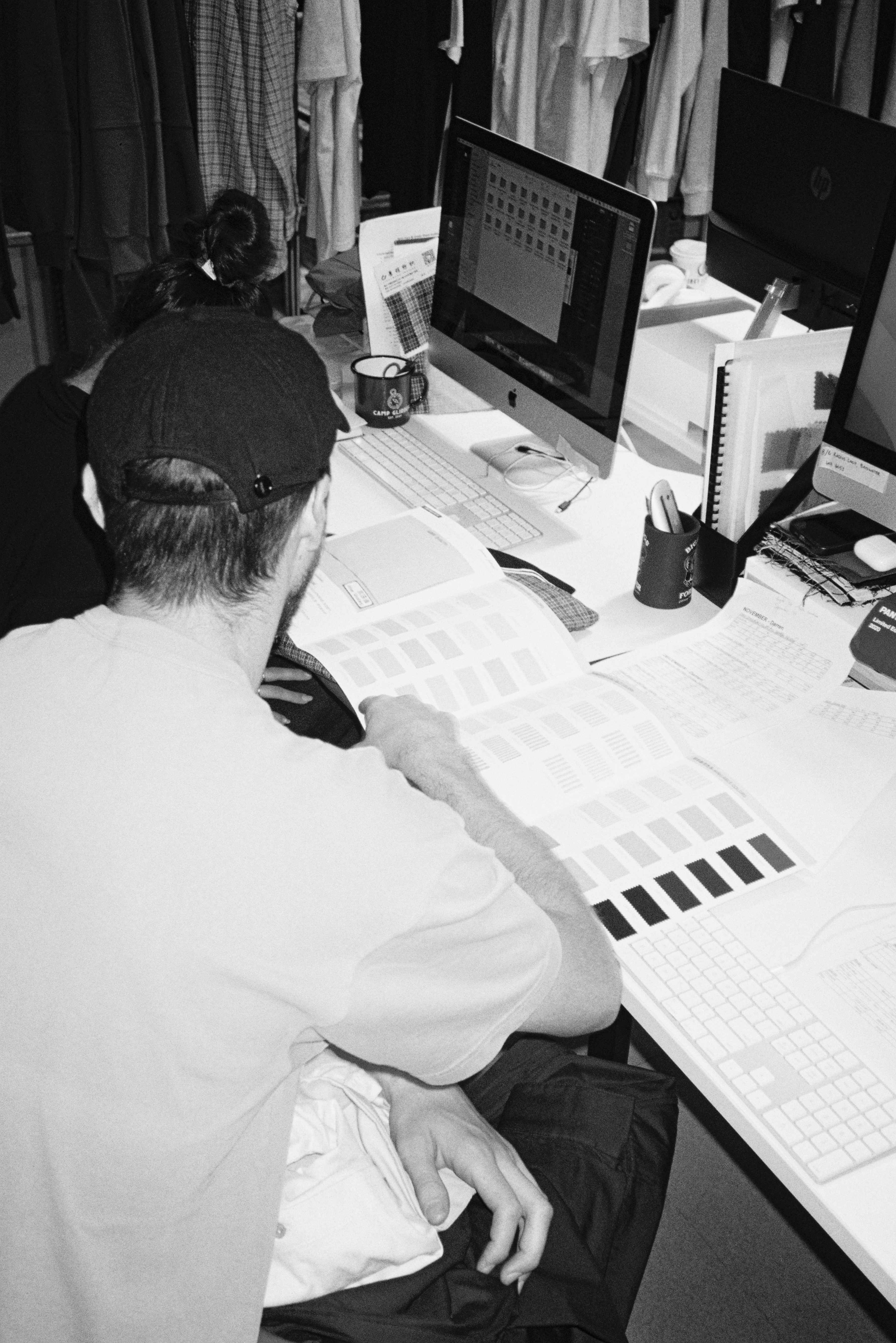

A lot has changed since Oli started in 2012. I was 17 years old, printing t-shirts from my bedroom and had no clue about business. Over the years the brand has grown and, as a person, so have I. You ask more questions and weigh up what is important.

For me and us at Oli this includes the environment, the people and trying to spark change for the better. We spend so much time at Oli working on and growing the brand and the culture. It is our responsibility to not only do the right things but to also set good examples.

We’re still small but we plan on being around for a long time, so we want to build practices and ethics which pave the way for good.

Introducing our do good project

This initiative allows us to have open discussions about our achievements and the areas where we aim to improve.

By doing so, we can avoid greenwashing and foster meaningful conversations, equipping you with the information needed to make informed choices.

As a community-driven brand, we value the power of our people, so if you have ideas, we want to hear from you.

Processes

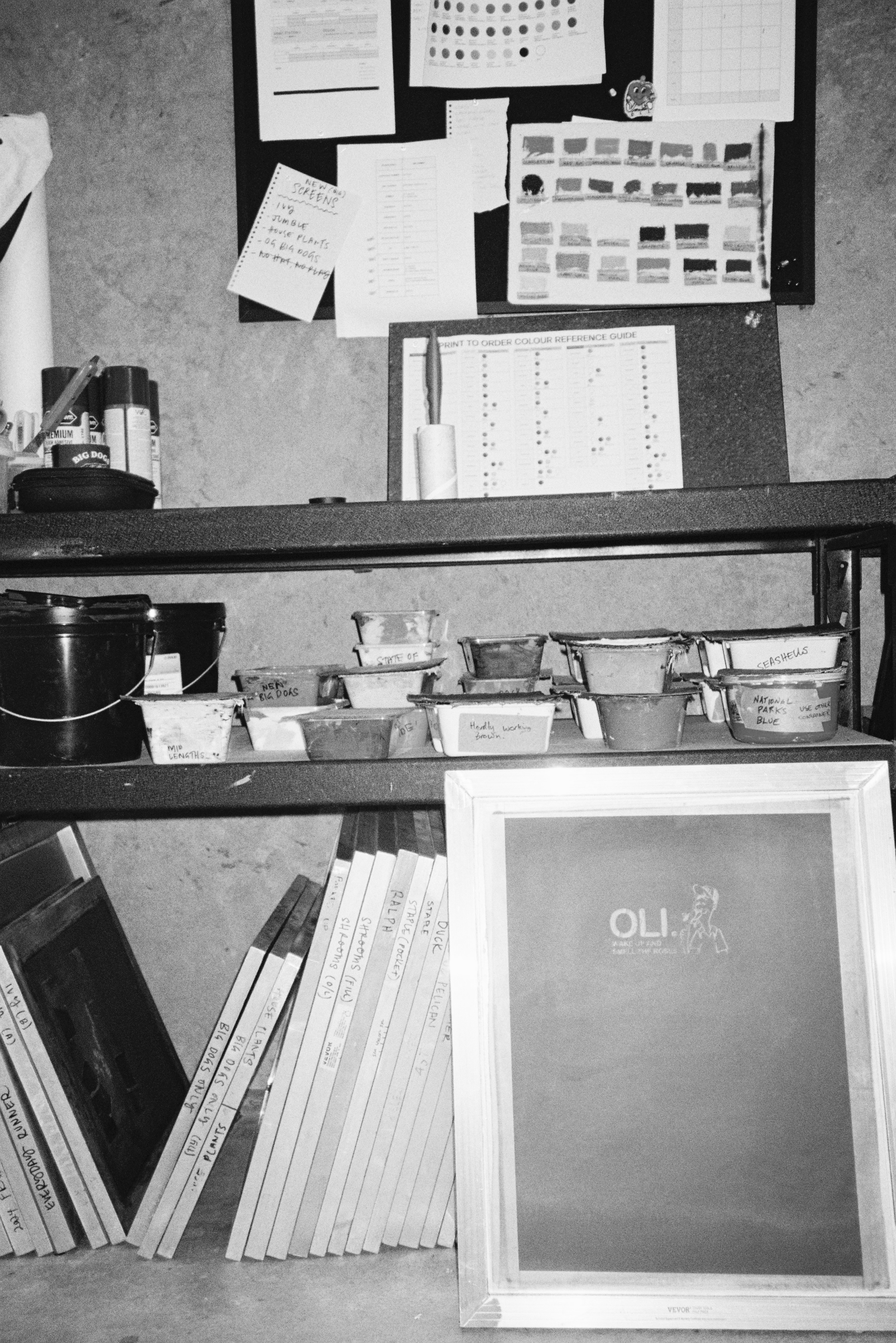

We eliminated single-use bags from our Northbridge Store in 2016 and have since removed plastics from our packing process.

As of 2019, all online orders are shipped in mailers made from certified corn starch and vegetable-based materials, which are fully compostable, even in landfill. In 2021, we introduced plantable swing tags made in Australia from recycled paper, featuring hemp string and no plastic. We have stopped importing products via air freight.

Products

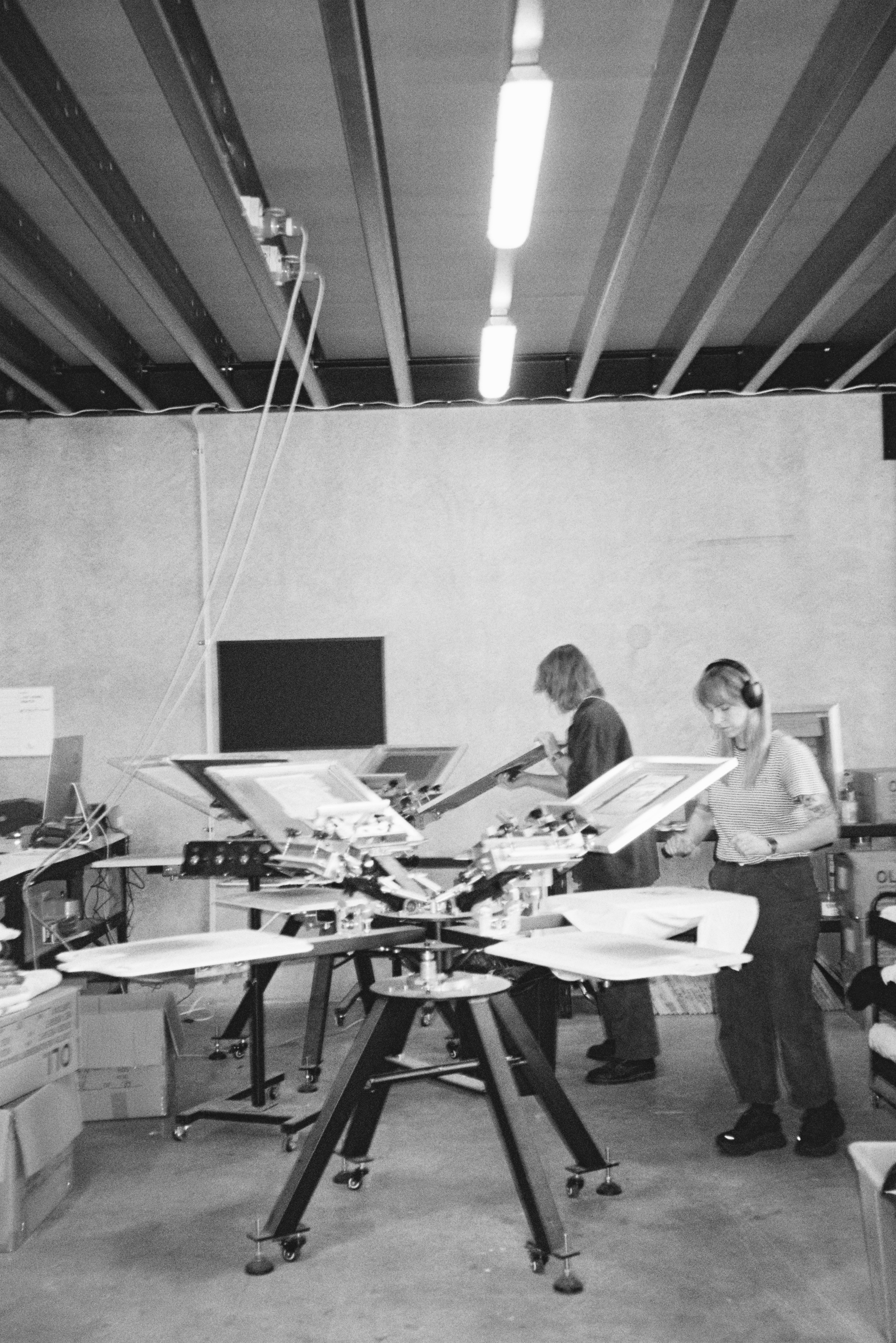

We launched our Pre Loved Program in 2023 to extend the lifecycle of Oli garments while supporting young people in need. In 2021, we introduced more sustainable fabrics like hemp, linen, and organic cotton, and replaced all blank t-shirts with our custom cut-and-sew options, minimising waste.

We prioritise limited production to avoid fast fashion, ensuring high-quality, long-lasting products. We collaborate with four specialised manufacturers for consistent, well-made items, fostering good relationships and fair pricing.

Additionally, we source stickers and printed materials, including return slips and swing tags, from Australian manufacturers using recycled paper.

people

We raised $36k for the Lord Mayor’s Relief Fund to support those affected by the Perth bushfires in 2020.

In 2021, we collaborated with Teach Learn Grow (TLG) to raise nearly $10k for better education for rural and disadvantaged kids.

We also partnered with Volunteering Western Australia to create a non-profit Oli x VWA t-shirt, engaging thousands of young people in volunteering.

In 2022, we teamed up with Perth Is OK! to raise over $17k for the mental health organisation Zero2Hero.

We continue to work with the Happiness Co Foundation, raising over $10k for their youth programs.

We collaborate with schools to discuss career pathways and are committed to strive for diversity within our team.